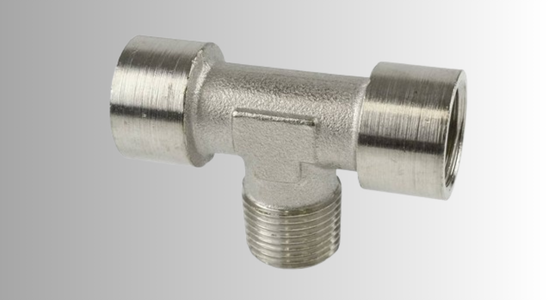

Sri Krishna Steel emphasizes quality control throughout their manufacturing process, adhering to international standards such as ASTM, ASME, and DIN. Each Tee fitting undergoes rigorous testing for strength, durability, and dimensional accuracy. This commitment to quality ensures that customers receive reliable products that perform efficiently in demanding environments, thereby enhancing safety and operational efficiency.

Tee

Home » Our Products » Stainless Steel Pipe Fittings » Tee

- Our Products Range

Tee

Our Product Range

Our Product Range

Sri Krishna Steel is renowned for manufacturing high-quality pipe fittings, including the versatile “Tee.” The Tee fitting is an essential component used in various piping systems to connect three pipes, allowing fluid or gas to flow in different directions efficiently. Made from premium materials such as stainless steel, carbon steel, or galvanized steel, Sri Krishna Steel ensures durability and resistance to corrosion, making their Tee fittings suitable for diverse industrial applications.

The Tee fittings produced by Sri Krishna Steel come in various sizes and specifications to meet the specific needs of clients across industries like plumbing, oil and gas, chemical processing, and construction. These fittings are designed to withstand high pressure and temperature conditions, maintaining the integrity of the piping system. Their precise engineering guarantees a perfect fit, reducing the risk of leaks and ensuring long-term performance.

Features Of Tee

- Precise Design

- Material Durability

- Versatility

- Variety of Sizes

- Strength and Reliability

- Standard Compliance

Applications Of Tee

- Plumbing Systems

- Oil and Gas Industry

- Chemical Processing

- HVAC Systems

- Fire Protection Systems

- Agricultural Irrigation

Specifications of Tee

| Parameter | Specifications |

|---|---|

| Material | SS304, SS316, SS321, or other stainless steel grades |

| Standard | ASTM A403, ASME B16.9, MSS SP-75, DIN 2605 |

| Type | Equal Tee, Unequal Tee, Reducing Tee |

| Size Range | ½ inch to 24 inches (or as per standard) |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500 (based on pressure class) |

| Wall Thickness | Schedule 40, Schedule 80, Schedule 160, Sch 10, Sch 40, etc. |

| End Connection | Butt weld, socket weld, threaded, buttweld socket weld |

| Temperature Range | -196°C to +800°C (dependent on material grade) |

| Corrosion Resistance | High resistance to corrosion, suitable for aggressive environments |

| Application | Chemical, petrochemical, water treatment, food processing, etc. |

| Finish | Mill finish, polished, or customized as per requirement |